Products with promotional print

Customisation with your desired print

As a business owner it is particularly important to stand out from the masses and exude uniqueness.

Are you looking for something special for your customers, employees and partners? A small compliment with heart and soul? Our likeable gift ideas are particularly suitable for this!

Make it to your product!

Printing your logo on our products can increase the visibility and awareness of your brand. Individual refinement turns a likeable gift item into a real eye-catcher with promotional and recognition value.

A well-designed gift is usually visible to your customers, employees and partners on a daily basis and is positively associated with your brand. For example, Mr Bert® that is pressed daily to relieve stress - an absolute win-win situation for you and the recipient.

What can be printed on?

Whether it's a squeaky duck, Mr Bert® or a cuddly toy with a mini T-shirt, almost every product in our collection can be customised with a slogan, logo or motif of your choice.

- Cuddly toy and accessories

- Squeaky ducks

- Anti-stress gifts

- Dog toys

- Key chains

- Reflectors and visibillity

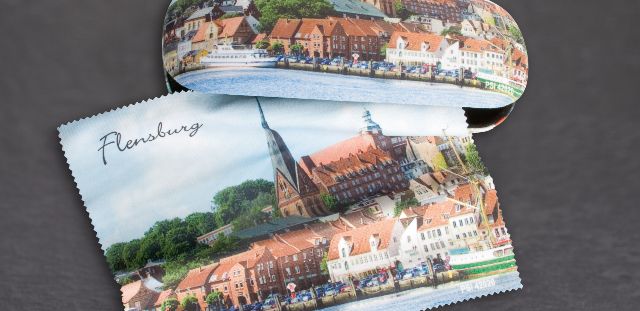

- Screen Cleaner

Logo printing is possible from a small quantity and in various printing processes.

Please contact us, together we will keep your personal advertising message.

Attachment positions

Customising technologies

![DIREKTTRANSFER[plus]](/pics/teaser_direkttransfer-plus_oekotex_mob,modulecms,GwxpE2kwX2i7ViZ0yqXyQQ_m.jpg)

New printing process, new possibilities: Upgrade for digital print transfer!

Direct transfer printing is getting an upgrade. From now on, coloured accessories and textiles can also be printed perfectly using transfer printing. We print your desired design in CMYK + WHITE and thus achieve a brilliant result. Whether finest details or large-scale motifs, single-colour and multi-colour logos or halftone printing and gradients - everything is possible!

The new transfer prints for textile accessories, cuddly toys, key rings and co. are produced in-house on our own new transfer printing machine. This gives you the opportunity to order samples from quantity 1, making it even easier to generate important leads.

Advantages:

- Low upfront costs

- No more register inaccuracies

- multi-coloured logos and photo-realistic

- motifs - even on dark textiles

- Gradients and shading possible

Requirements for the print data:

- Vector data (-.ai, -.eps, -.cdr, -.pdf)

- Fonts converted to paths, recommended font thickness from approx. 1-2mm

- no fine hairlines

- Pixel graphics (PNG with transparent background)

- Print data not mirrored!

- If possible, no special colours, as printing is in CMYK.